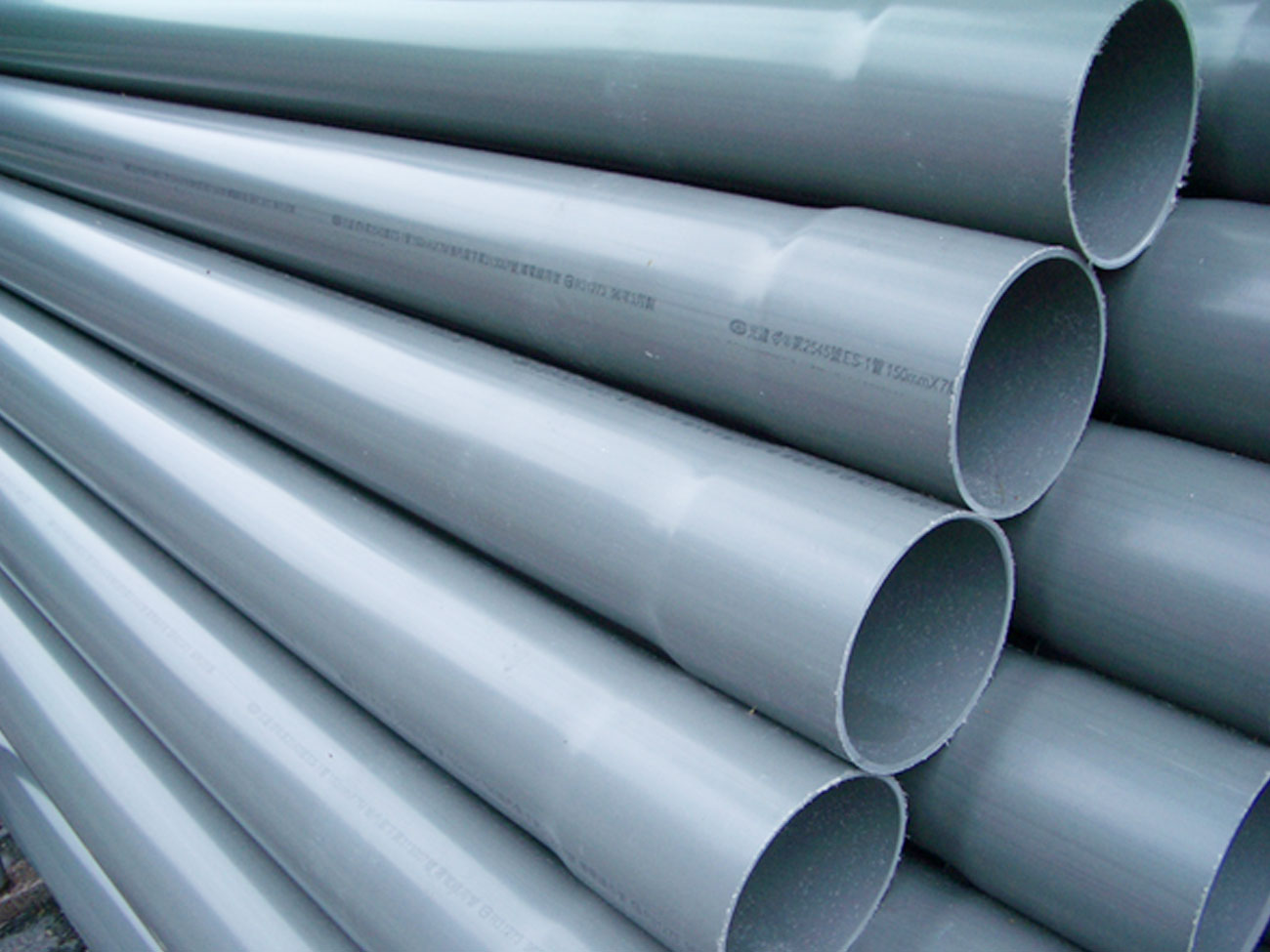

Unit:㎜

| Item | A pipe (thin) | ||||

| External diameter & tolerance | Thickness | Internal diameter | Length | ||

| Min. | Tol. | ||||

| 40 | 48±0.2 | 1.8 | ﹢0.4 | 44 | Marked value ﹢30 -10 |

| 50 | 60±0.2 | 1.8 | ﹢0.4 | 56 | |

| 65 | 76±0.3 | 2.2 | ﹢0.6 | 71 | |

| 80 | 89±0.3 | 2.7 | ﹢0.6 | 83 | |

| 90 | 100±0.4 | 3.1 | ﹢0.6 | 94 | |

| 100 | 114±0.4 | 3.1 | ﹢0.8 | 107 | |

| 125 | 140±0.5 | 4.1 | ﹢0.8 | 131 | |

| 150 | 165±0.5 | 5.1 | ﹢0.8 | 154 | |

| 200 | 216±0.7 | 6.5 | ﹢0.8 | 202 | |

Unit:㎜

| Item | B pipe (thin) | ||||

| External diameter & tolerance | Thickness | Internal diameter | Length | ||

| Min. | Tol. | ||||

| 16 | 22±0.2 | 2.7 | ﹢0.6 | 16 | Marked ﹢30 -10 |

| 20 | 26±0.2 | 2.7 | ﹢0.6 | 20 | |

| 25 | 32±0.2 | 3.1 | ﹢0.8 | 25 | |

| 30 | 38±0.3 | 3.1 | ﹢0.8 | 31 | |

| 40 | 48±0.3 | 3.6 | ﹢0.8 | 40 | |

| 50 | 60±0.4 | 4.1 | ﹢0.8 | 51 | |

| 65 | 76±0.5 | 4.1 | ﹢0.8 | 67 | |

| 80 | 89±0.5 | 5.5 | ﹢0.8 | 77 | |

| 90 | 100±0.6 | 5.6 | ﹢0.8 | 88 | |

| 100 | 114±0.6 | 6.6 | ﹢1.0 | 100 | |

| 125 | 140±0.8 | 7.0 | ﹢1.0 | 125 | |

| 150 | 165±1.0 | 8.9 | ﹢1.4 | 146 | |

| 200 | 216±1.3 | 10.3 | ﹢1.4 | 194 | |

Specification:

| Test Items | Performance requirements | Test standard | |

| Tensile Strength Test | above 45MPa at 23℃ | CNS 1298 K3004 | |

| Pressure resistance for pipe | No leakage,fracture or ditortion | ||

| Pressureresistance at joint port | No leakage, | ||

| Flattening resistance | No fissure or cracking | ||

| Vicat softening temperature | 76℃ or higher | ||

|

浸漬試驗 (Immersion Test) |

Distilled Water | Within ±0.2mg/㎝² | |

| 10% Sodium Chloride Solution | Within ±0.2mg/㎝² | ||

| 30% Solfuric Acid Solution | Within ±0.2mg/㎝² | ||

| 40% Sodium Hydroxide Solution | Within ±0.2mg/㎝² | ||

| 40% Nitric Acid Solution | Within ±0.2mg/㎝² | ||

Unit:㎜

| Item | E pipe | ||||

|

External diameter & tolerance |

Thickness | Internal diameter |

Length & tolerance |

||

| Mid. | Tolerance | ( reference) | |||

| 16 | 22±0.2 | 1.8 | ﹢0.4 | 18 |

Marked value. +30 -10 |

| 20 | 26±0.2 | 1.8 | ﹢0.4 | 22 | |

| 28 | 34±0.3 | 2.7 | ﹢0.6 | 28 | |

| 35 | 42±0.3 | 3.1 | ﹢0.8 | 35 | |

| 41 | 48±0.4 | 3.1 | ﹢0.8 | 41 | |

| 52 | 60±0.5 | 3.6 | ﹢0.8 | 52 | |

| 65 | 76±0.5 | 4.1 | ﹢0.8 | 67 | |

| 80 | 89±0.5 | 5.1 | ﹢0.8 | 78 | |

| 100 | 114±0.6 | 6.6 | ﹢1.0 | 100 | |

| 125 | 140±0.8 | 7.0 | ﹢1.0 | 125 | |

| 150 | 165±1.0 | 8.5 | ﹢1.4 | 148 | |

| 200 | 216±1.3 | 10.5 | ﹢1.4 | 194 | |

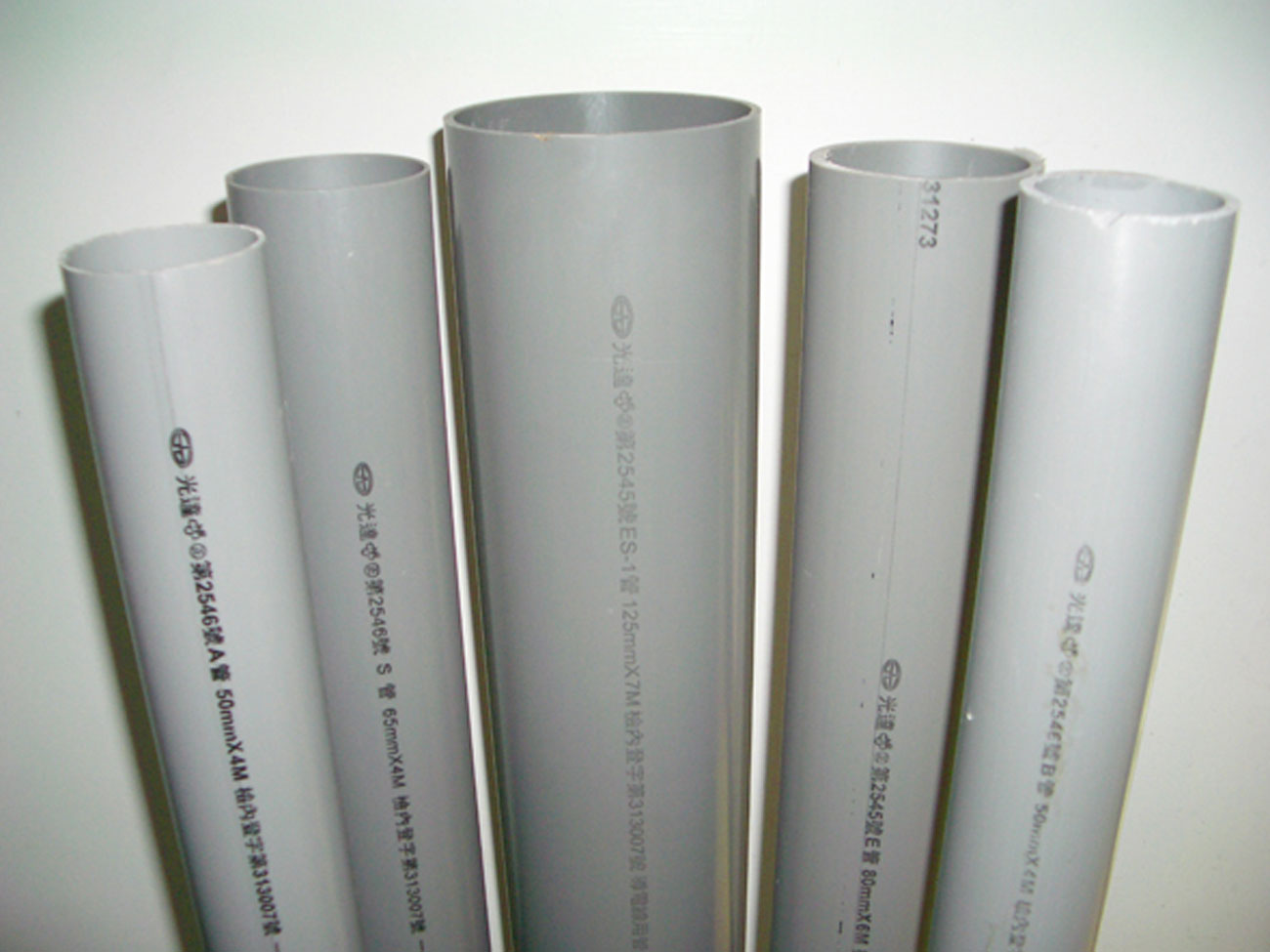

Unit:㎜

| Item | ES-1 pipe | ||||

|

External diameter & tolerance |

Thickness | Internal diameter |

Length & tolerance |

||

| Mid. | Tolerance | ||||

| 80 | 89±0.5 | 2.7 | ﹢0.6 | 83 | Marked value. +30 -10 |

| 100 | 114±0.6 | 3.6 | ﹢8.0 | 106 | |

| 125 | 140±0.8 | 4.1 | ﹢0.8 | 131 | |

| 150 | 165±1.0 | 5.1 | ﹢0.8 | 154 | |

Specification:

| Test Items | Performance requirements | Test standard |

| Resistance to flattening | Under a load of 1250 N, the outside diameterdeduction rate should be smaller than 25%, and after unload should be smaller than 10 %. The test specimen should be no crackle and broken with visual inspection. | CNS 1302 K3006 |

| Resistance to impact | At least 9 out of 12 test specimens should be passed with no crackle and broken and without deformation which may defer application. | |

| Insulation | No trip happened while testing | |

| Insulation resistance | Over 100 MΩ | |

| Flame resistance | All of 3 specimens should be passed. The flame should be distinguished automatically within 30 s after the source of fire moved away. | |

| Heat resistance | The plug gauge should pass through the pipe by its own mass |

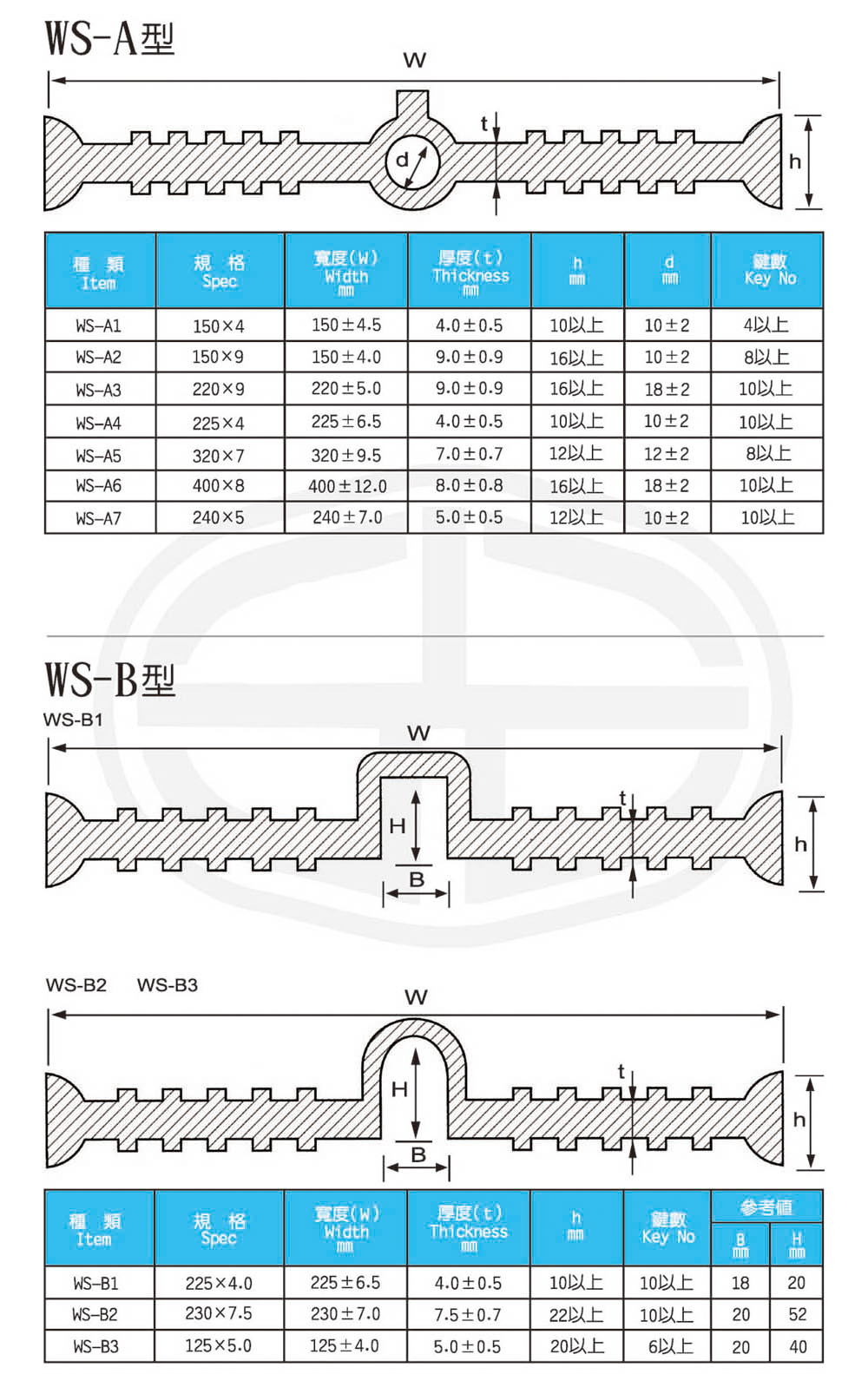

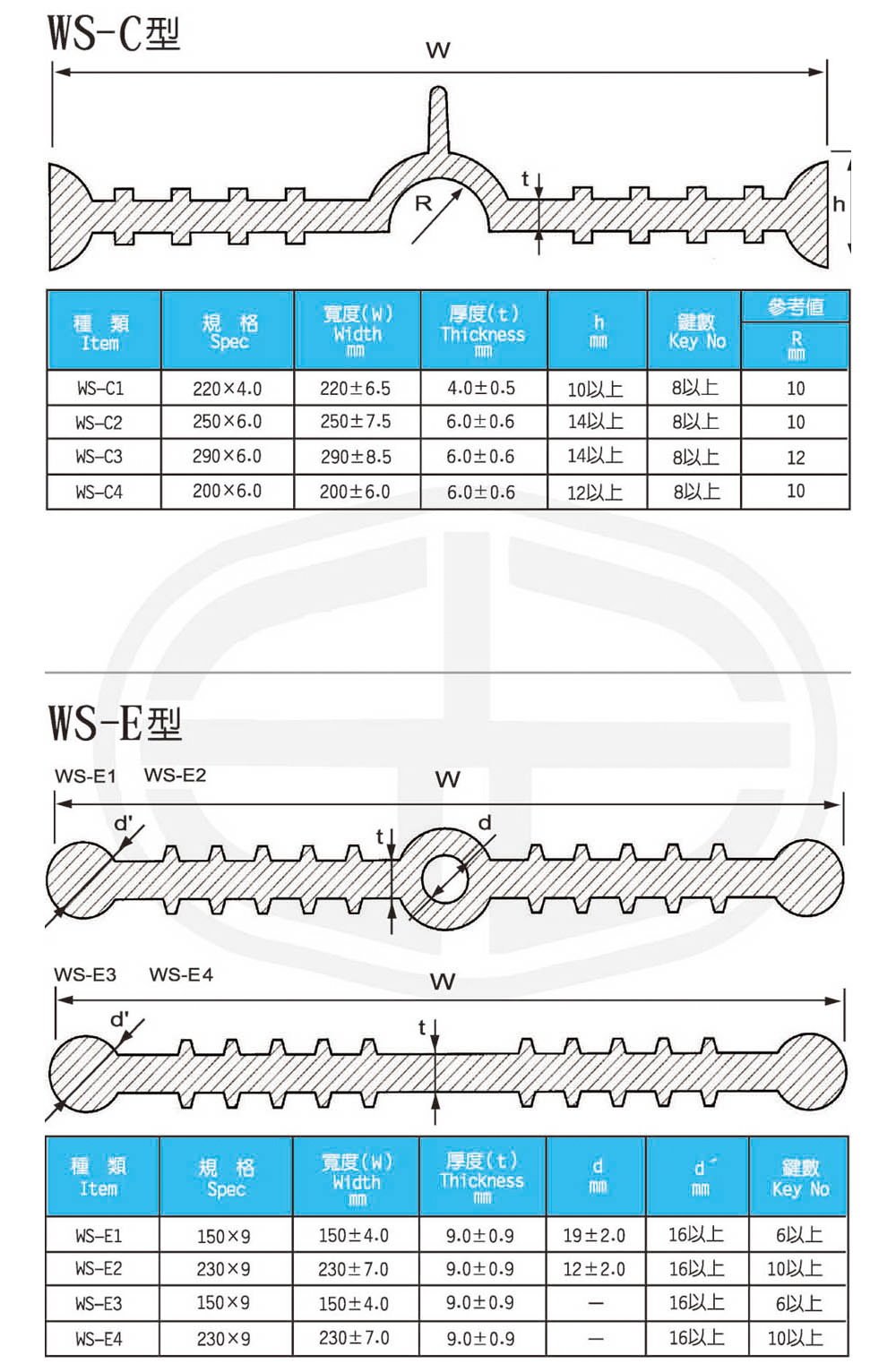

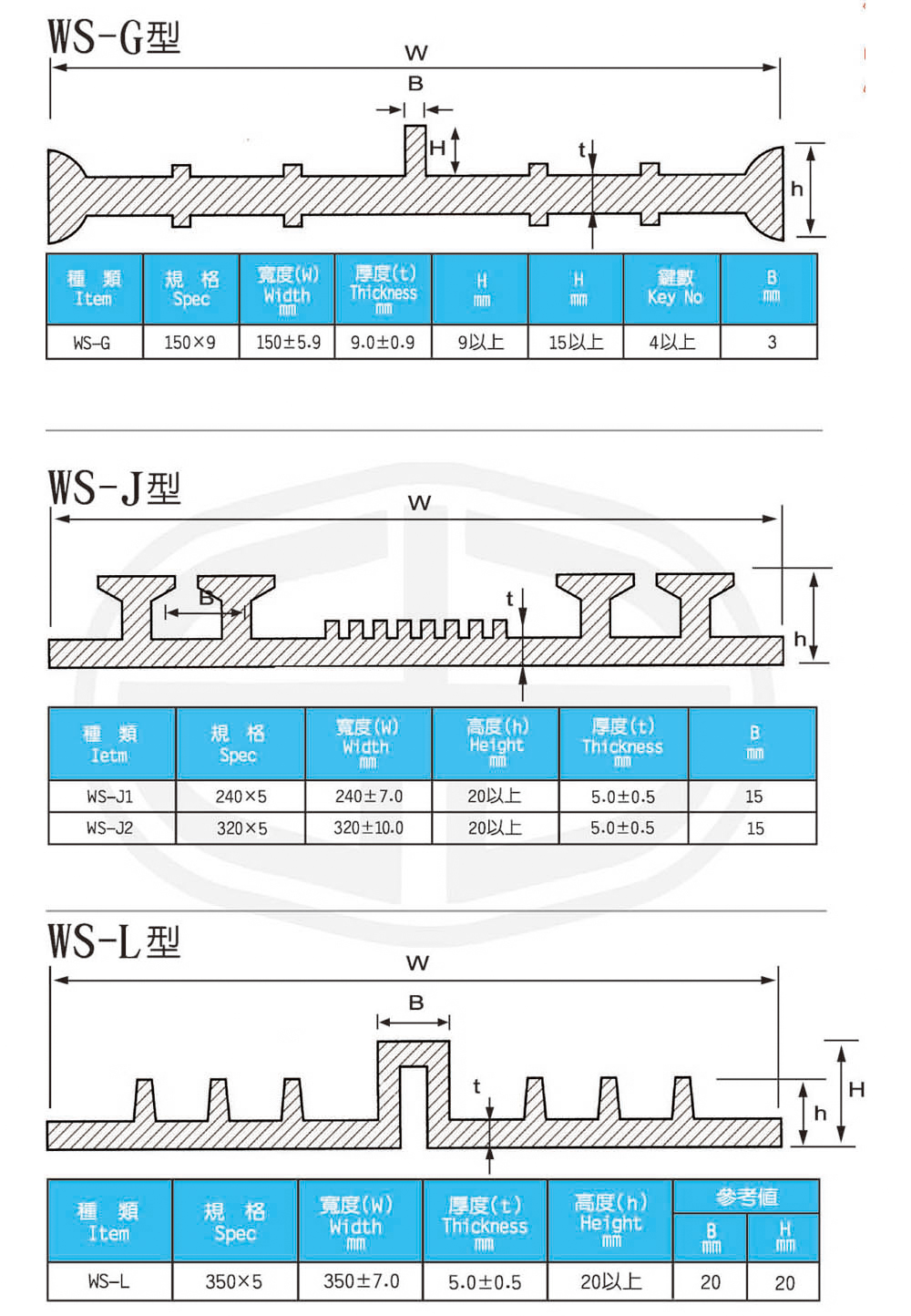

PRODUCTS

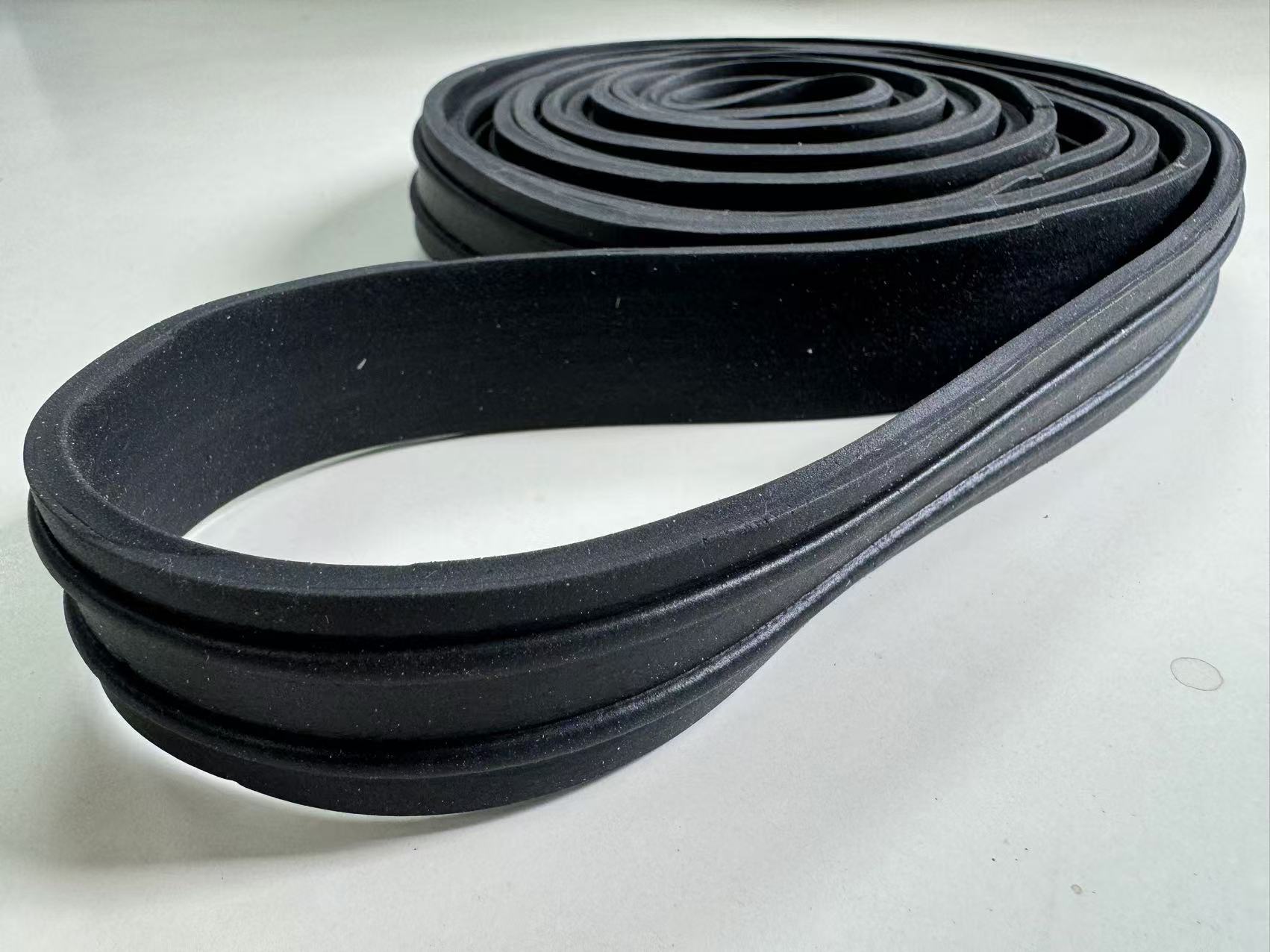

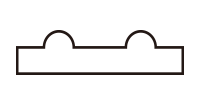

Water Stop

Water Stop

Water Stop

Water Stop

Water Stop1

Water Stop2

Water Stop3

Water Stop CNS

PRODUCTS

Swell stop

Swell stop

Swell stop

Swell stop

Swell stop

Our products have been widely used in Taiwan MRT projects. Regarding expansion rate, tensile strength, and elongation, we can customize according to the requirement. Please call for further inquiries.

| 25 mm (W) 7 mm (T) |

20 mm (W) 7 mm (T) |

20 mm (W) 10 mm (T) |

30 mm (W) 5 mm (T) |

10 /20 /30 mm (W & T) |

|

|

● | ||||

|

● | ● | ● | ||

|

● |

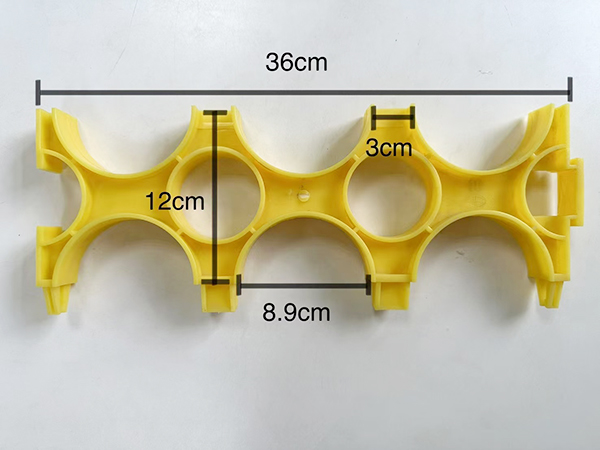

PRODUCTS

Drain Pipe

Drain PipeDownload Brochure